MICROFINISH VALVES PVT. LTD.

ABOUT US

Microfinish will always strive to be the number ONE supplier of valves, pumps and process automation in the markets we serve. As part of our Quality Assurance system, we are continually looking for ways to improve not only our product line, but also the way we interact with and serve our customers at every level. We will always look at expanding into new geographical areas in order to provide technology that will help our customers achieve their business goals.

Turnover

100 Cr - 250 CrNumber of Employees

10-19Business Type

1. ManufacturerYear of Incorporation

Address

838RGhhcndhZCxLQVJOQVRBS0E=Facilities Available

N/AAwards/Appreciation

N/AType of Company

Pvt LtdBrand Name

Certification

N/AClients

N/ABusiness Category

1. Mechanical Services2. Instrumentation

Experience

| Year | Company | Job Description | PO/WO/Completion Certificate |

|---|---|---|---|

Our Products

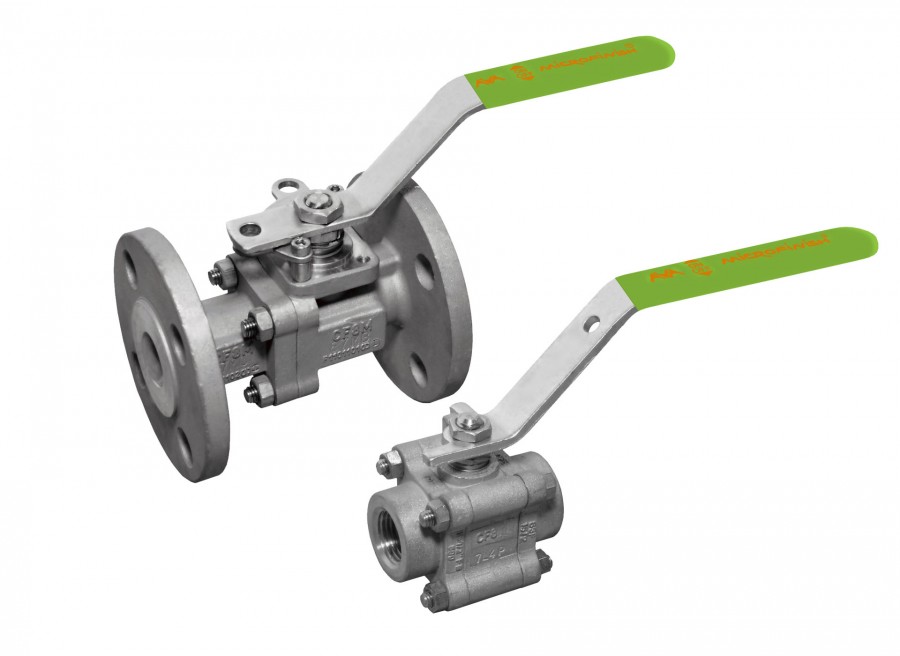

Floating Ball Valve

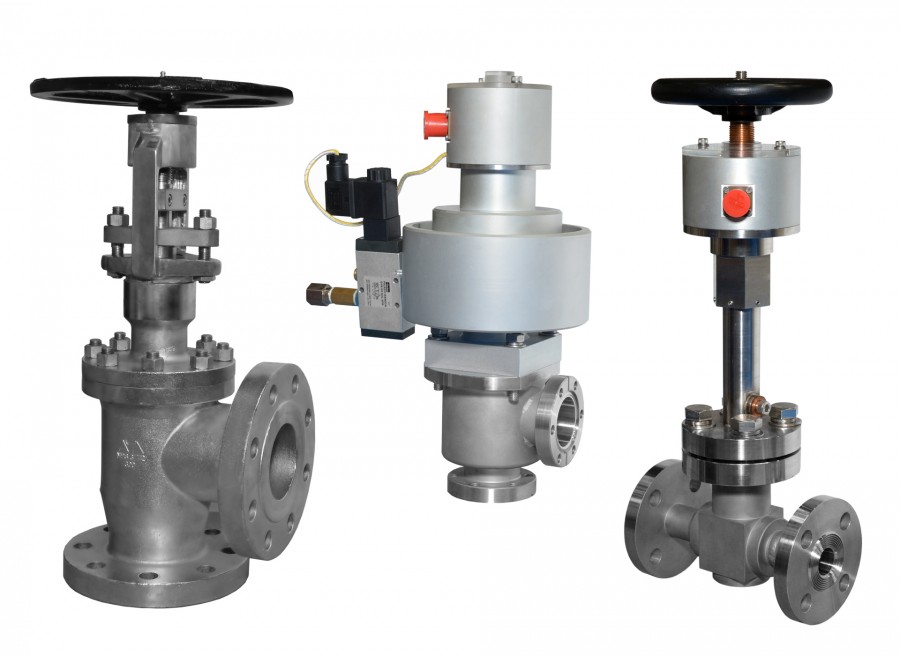

Trunnion Mounted Ball Valve

Low Emission Valves

Cryogenic Valves

Metal Seated Valves

Oxygen Service Valves

Valves for Chlorine Service

Bellows Seal Valves

Swing Check Valves

Enquiry

Say Something