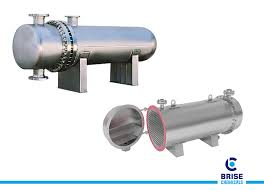

ASME Heat Exchangers & Vessels

ABOUT US

ASME Heat Exchangers & Vessels has been established in the year 1995, by Rajan. We provide all types of Design, Manufacture, Testing & Supply of all Type Heat exchangers and Pressure Vessels & Heavy Fabricators. We have over 20 years experience, we are the experts in Heat Exchangers and Oil Coolers – it’s our life.

Our Objectives are

To acquire market leadership by providing timely and reliable services.

To ensure effective performance of as per the customer requirements.

To conduct efficient business & establish long-term customer relationship.

To respond to the needs of customer requirements and be alert to customer’s needs.

To provide prompt support services to customer.

To provide cost effective solutions to customers.

To maintain a self motivated team of employees with full empowerment for continual improvement.

Turnover

<1 Cr.Number of Employees

<10Business Type

1. Service Provider / Contractor2. Trader / Retailer/ Distributor

Year of Incorporation

1995Address

548QmFuZ2Fsb3JlLEtBUk5BVEFLQQ=Facilities Available

N/AAwards/Appreciation

N/AType of Company

ProprietorshipBrand Name

Certification

N/AClients

N/ABusiness Category

N/AExperience

| Year | Company | Job Description | Completion Certificate |

|---|---|---|---|

Our Products

Shell and Tube Heat Exchangers

U Tube Bundle Heat Exchangers

Air Cooled Heat Exchangers

Oil Coolers

Condensers

Tanks & Vessels

Enquiry

Say Something